You don’t have to know all the answers, just where to find them. Our reading club clearly explains the most important terms in pool technology. Should you have specific questions regarding your project, please feel free to send us an e-mail. We’re happy to help.

blank

Backwashing

Filters must be backwashed regularly in order to remove dirt particles that have been filtered out of the pool water. With pool pumps backwashing is carried out by simply reversing the flow direction of the water current. Thus dirt particles are loosened from the filter sieve and led with the waste water to the sewage. The backwash procedure is carried out manually (see instruction manual) and should be followed by the rinsing procedure.

Ball bearings

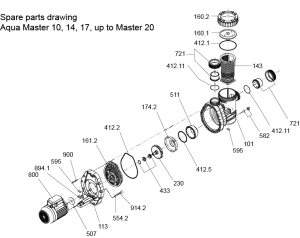

Ball bearings are a type of anti-friction bearing in which several balls serve together as rolling elements. In Aqua TechniX pool pumps they support the power on moving parts such as the motor shaft, reduce performance loss due to friction and minimize material wear. The ball bearings are wear parts.

Circulation pump

All Aqua TechniX pool pumps are circulation pumps, also known as centrifugal pumps. An impeller turns at high speed inside the pump housing and ensures the circulation of the pool water whilst simultaneously cleaning and filtering. The rotating impeller is driven by a motor which is structurally separate from the pump housing (electrical separation).

Characteristics

Characteristics show the pool pump performance per hour (m³/h) depending on the flow rate (m). In practice, the characteristics serve to determine the pump’s operating point (working point) or optimum rate of efficiency.

Continuous sound intensity level

The continuous sound intensity level describes the volume that constantly emanates from a sound source. A standard conversation between two people creates, for example, a sound pressure level of approx. 60 decibels (unit dB(A)). The values of the Aqua TechniX pool pumps are measured according to DIN 45635 and can be obtained directly from us upon request.

Counter swim unit

A counter swim unit provides a slight current in the pool so that you can swim as though in a river, even in small pools. The centrifugal pump integrated in a counter swim unit primes the pool water with a low suction speed and leads it under high pressure through one or more nozzles underneath the water level and back into the pool. Counter swim units such as the Aqua Flow Jet add more variety to every pool and not only increase the amount of fun for children, but also create a pleasant massage and whirlpool effect.

Electrical separation

Aqua TechniX pool pumps and counter swim units guarantee electrical separation between electricity and water. The pump’s design principle and the use of insulated plastic parts ensure that the motor shaft does not come into contact with the pool water.

Filter dimensioning

The dimensioning or required sand filter size is calculated from the flow rate of the pool pump and the flow speed in the filter. Generally speaking, the slower the flow speed, the more effective the filter is. Therefore the flow speed should not exceed 50 m/h.

Flow rate

The flow rate describes the highest water quantity that can be handled by the pool pump. When selecting a pool pump, the flow rate and total dynamic head are the most important performance parameters. Both values are technically associated and define the operating point.

GS sign

The GS sign stands for „Geprüfte Sicherheit“ (certified safety) and certifies a product as corresponding to the requirements of the product safety law (ProdSG § 21) established in the German (DIN) and European (EN) standards. The GS sign is assigned as a technical seal of approval by independent examination boards such as the TÜV. Aqua TechniX products are up to date with current technology and are tested regularly.

Mechanical seal

Mechanical seals in pool pumps are rotating seals that seal the motor shaft off from the housing wall. Mechanical seals consist of two components which slide against each other (slide ring and counter ring) and are wear parts.

Non-self-priming pumps

As opposed to self-priming pool pumps, non-self-priming pumps such as the Aqua Splash are unable to transport air. Therefore non-self-priming pool pumps must be installed below the water level so that the pool water can flow into the pump independently.

Operating capacitor

An operating capacitor in the pool pump is a technical component, which serves to save or charge electrical energy like a battery. The amount of capacity is measured in Farad (unit F). Operating capacitors are built into pool pumps from Aqua TechniX in order to absorb changes in voltage. These components belong to the wear parts.

Operating point

The operating point (or working point) is a specific point on the characteristics diagram or curve of a pump, which is defined as a reference for the intended application situation. Selecting the optimum pool filter pump depends on several factors such as flow rate and total dynamic head.

Pipe assembly

Depending on the type of pump, the unions enclosed (or teflon band for threaded connections) are used to connect the pipework. ABS unions have a minimum curing time of 12 hours. Important: plastic threads cannot be sealed using hemp.

Pipe dimensioning

In the pipework of a pool unit there is normal, physical frictional loss. The general rule of thumb is: the higher the flow speed of the water, the higher the frictional loss. This should already be taken into consideration at the planning stage so that the pool technology can work efficiently. The flow speed or frictional loss can be calculated using the frictional characteristics and thus the optimum pipe dimensions can also be calculated.

Priming speed

The priming speed in metres per second (unit m/s) describes the water’s flow speed or the suction performance at a suction point and is an important measurement when evaluating a counter swim unit. The priming speed of the Aqua TechniX counter swim unit Aqua Flow Jet corresponds to the relevant EU standards at the least.

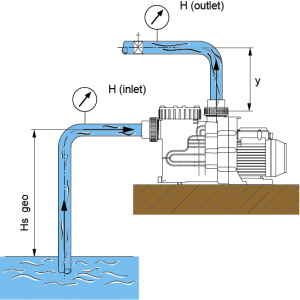

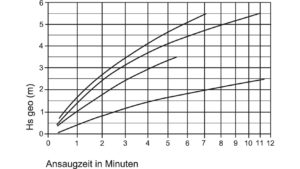

Priming time

The pump’s priming time is the amount of time a pump needs to prime the water until the suction line is completely evacuated. The priming time doesn’t just depend on the pump’s construction and capacity, but also on the length and diameter of the pipework and how high above the water the pump is placed (installation height).

Rinsing

Rinsing after the filter’s backwash cycle serves to flush. Any residue or erosion from the filter materials will be flushed into the waste water. Rinsing should take approx. one minute.

Self-priming pumps

As opposed to non-self-priming pumps, self-priming pumps can handle air and (after the pump initially being filled) release it again independently via the lid in the filter housing. Self-priming pumps are typical circulation pumps for private garden and swimming pools because they can be installed above or below the water level.

Strainer basket

The strainer basket is one of the most important pool technology components, as it keeps course debris away from the pool pump and therefore protects it from blockages and faults. We recommend regular visual inspections – once a week is best. Important: depending on the pool location, the strainer basket may become dirtier faster in autumn (leaves). This will reduce the pool pump’s flow rate so that the circulation of the pool water is no longer sufficient.

Total dynamic head

The total dynamic head measures the height of the water level to the highest point of the pressure line, taking into consideration pressure loss caused by pipework and further components of the pool pump.

Water level

The water level describes the height of the water i.e. the surface of the pool water when it is still.

Wear parts

Whenever technical components move and come into contact with each other, operational wear occurs due to material abrasion (example: car tyres). As wear of such parts is physically unavoidable, wear parts are not covered under warranty. Aqua TechniX pool pumps and counter swim units are basically designed to be low maintenance. Typical wear parts such as mechanical seals and ball bearings should simply be replaced from time to time.

Winter storage

A circulation pump has to be completely drained by the end of autumn at the latest – certainly before the first frost – because the water in the pump would expand when frozen and damage the pool pump. The pump’s instruction manual explains this procedure in detail.